Five Reasons to Select Plastic Molding Manufacturing (PMM) as your Two-Shot Injection Molder

- Plastic Molding MFG

- Apr 4, 2024

- 2 min read

Plastic Molding Manufacturing has the largest base of Two-Shot Injecting machines in New England. PMM considers Two-Shot Injection Molding to be one of the most effective ways to mold plastics with multiple materials and specific requirements.

Plastic Molding Manufacturing (PMM), a leading supplier of Two-Shot multi-component and material moldings, considers Two-Shot Injection Molding to be one of the most effective ways to mold plastic products with multiple materials and specific requirements. Here are five reasons why you should select PMM for its Two-Shot Molding capabilities.

Five Reasons:

1. Cost Benefits: Two-Shot molding eliminates added costs and secondary operations.

2. Reduced Time and Labor: The operations that previously required two machines, now only use one. Two-Shot molding eliminates secondary operations that would otherwise increase time and labor for a product to be completed.

3. Enhanced Product Quality: Improves overall quality control and product integrity.

4. Improved Compatibility and Material Options: PMM's experience and knowledge of selecting proper materials for increased product integrity allows for more safety with component adhesion, improved compatibility, and material options.

5. New Design Possibilities: Two-shot molding allows designs to have multiple colors, materials, and components. End-user performance is enhanced through non-slip grips, reduced vibration, noise dampening, water shields, drop protection, moveable components, and family molds. Mold Flows given added benefits and insight to product integrity.

In order to understand these benefits, it is important to know the difference between Two-Shot Molding and traditional Over-Molding processes.

Traditional Over-Molding process:

1. Base of product is molded with horizontal injection molding machine.

2. Mold base is then manually placed in a second mold that is run through a specialized vertical molding machine.

3. Insert molding and other secondary components required are then accomplished through separate machines, tools, and manual labor.

Two-Shot Injection Molding Process:

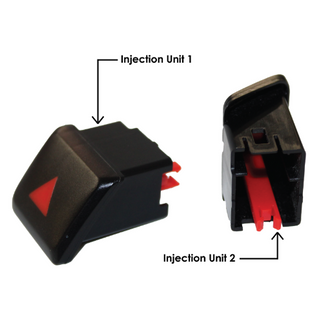

1. Two mold cavities are utilized in one rotatory molding machine with two injection units.

2. The top mold cavity serves as the base mold. The bottom mold cavity serves as the secondary molding operation, over-mold process.

3. Both shots of material are injected into the corresponding mold cavity.

4. The mold opens and rotates 180 degrees.

5. Finished molds from the bottom cavity are then ejected from the mold. The mold then closes, starting the cycle again.

Examples of products made via Two-Shot Injection Molding:

Learn more about PMM's Two-Shot Molding capabilities: https://www.plasticmoldingmfg.com/two-shot-molding