What to Ask About When Looking for Plastic Molding in the Defense Industry

- Plastic Molding MFG

- Aug 21, 2025

- 4 min read

Updated: Jan 12

Serving the Needs of the Defense Industry: The Role of Plastic Injection Molding

Serving the needs of the defense industry requires expertise and attention to detail. Plastic injection molding is an important manufacturing process in the defense sector, providing durable, precise, and lightweight components. Plastic molding is favored for its ability to produce complex shapes with tight tolerances, offering cost-effective solutions for both high and low-volume production runs compared to other materials.

The Importance of Plastic Injection Molding in Defense

Injection molding is an ideal manufacturing method for defense due to its high repeatability, access to a broad range of thermoplastics, and domestic production advantages. Few sectors rely more heavily on mission-critical plastic components than the Department of Defense (DOD) and military.

From battlefield equipment to aerospace systems, plastics play a vital role in supporting real-world missions where the stakes are high. The military's demand for lighter, more durable materials makes plastics an essential choice for various applications.

Injection molding also meets the strict performance requirements of defense-grade components. It enables the production of versatile parts with the tight tolerances needed for both offensive and defensive systems. Military contracts often specify exacting standards, and even minor deviations can result in a rejected batch. That’s why partnering with an experienced injection molder is key. The right team understands not only the tooling and design demands of military components but also how to deliver the precision and consistency these critical applications require.

Ask What are the Advantages of Plastic Injection Molding for Defense Projects?

Lightweight: Plastics are significantly lighter than traditional materials like metal, reducing the overall weight of equipment and improving troop mobility.

Durability and Strength: Plastics can be engineered to meet specific strength, temperature, chemical, and impact resistance requirements, making them suitable for harsh military environments.

Cost-Effectiveness: Injection molding can be a cost-effective solution for both prototyping and high-volume production, especially when compared to other manufacturing processes.

Design Flexibility: Injection molding allows for the creation of complex shapes and intricate geometries while adhering to strict quality requirements, enabling the production of highly specialized and customized parts.

Rapid Prototyping: Rapid injection molding techniques enable quick turnaround times for prototypes, allowing for faster product development cycles.

Versatility: A wide variety of plastics are available, allowing for the selection of the optimal material for each specific application.

Secondary Operations: Injection molding processes can be combined with secondary operations like sonic welding and heat staking, along with various finishing techniques to enhance functionality and performance. Combining materials can improve functionality, grip, insulation, and vibration dampening aspects.

Ask about ITAR Standards

ITAR (International Traffic in Arms Regulations) is a set of U.S. government rules that control the export and sharing of military and defense-related items and information. These rules help protect national security and support U.S. foreign policy. Any company that makes, sells, or shares defense-related products or data must follow ITAR regulations. It is vital to work with an ITAR-compliant and experienced molder.

While some parts are relatively straightforward, others fall under strict government regulations of ITAR. Working with a manufacturing partner who understands compliance requirements is essential to ensuring quality, consistency, and approval at every stage.

Ask About Their Experience with Defense Components

A company should have decades of experience producing sensitive critical components that meet tight tolerances and exact specifications. This is when reliability is critical, and lives depend on it.

Common military applications for molded plastics include:

Protective housings and enclosures

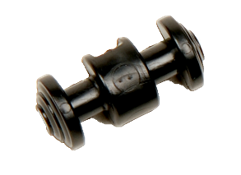

Cable connectors and wire insulation

Lightweight structural components

Seals, gaskets, and vibration dampening elements

Plastics are often integrated into larger assemblies alongside metals or other materials. Advanced techniques like over-molding make it possible to create more complex, high-performance designs. By combining metal and plastic, you get the best of both worlds—strength, durability, and weight savings.

What Type of Materials are Needed for the Defense Industry?

Some of the most common materials used in the defense industry are:

High Heat Resins: PEEK, Ultem, and PPA offer excellent resistance to varying temperatures and chemicals, making them suitable for demanding aerospace and defense applications.

Nylon: Provides strength, resilience, and chemical endurance, often used in tactical gear and vehicle components.

Polycarbonates: Offer stability and impact resistance, good for applications requiring precision and durability.

Other Materials: ABS, PMMA, and various glass-filled and flame-rated plastics are used depending on the specific requirements of each application.

Ask About Quality

When reliability is critical, and the mission depends on it, quality is paramount. There’s no room for error when lives hang in the balance. Ensuring your manufacturer can handle the project and has experience with proven reliability is essential. Military products operate in some of the toughest environments imaginable. Truck parts must endure constant shocks, impacts, and heavy vibrations. Other components face extreme temperatures—both scorching heat and freezing cold—or require chemical resistance due to exposure in the field. With the right thermoplastic materials, these performance demands can be met reliably.

Plastic Molding Mfg is more than just an injection molding manufacturer—We are a Dependable Partner that You Can Count On. Our team is dedicated to delivering high-performance products and turn-key solutions for defense/military components that meet the highest standards for zero-failure applications and will always perform as expected at the most critical times.

Our Services

We offer:

Engineering Support

Remote Visual Inspection

Material and Product Development

Project Management

Tooling

Safety Consciousness